FMCSA allows company alternative cargo securement technique

The Federal Motor Carrier Safety Administration has granted a five-year exemption that allows a company to use a cargo securement system that differs from what is required in the regulations.

FMCSA’s notice about granting the exemption to Delta, Ohio-based K & L Trucking was published in the Federal Register on Friday, Dec. 4.

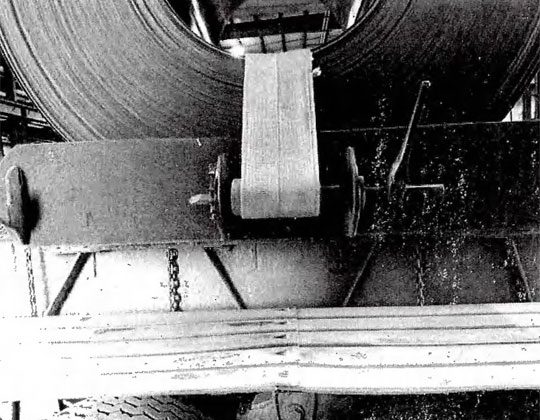

Instead of the traditional, two-strap cross pattern for the tie-downs on the coils, K & L uses a single, two-ply, nylon-Kevlar strap to attach the coils to a customized metal carrier affixed to the bed of its trailers.

In its application for exemption, K & L said that its business consists entirely of transporting metal coils to a location that is less than 2 miles away.

“As a result, K & L’s trucks never travel faster than 30 miles per hour on the road as the drive is simply too short for the trucks to accelerate to a higher speed,” the company wrote. “Practically speaking, the additional weight of the carriers makes them prohibitive for longer hauls but remains feasible for shorter hauls and better provides for the safety of workers and the general public.”

FMCSA’s regulation places three requirements on the transportation of metal coils weighing more than 5,000 pounds. Those requirements are the use of a chocks, wedges, or cradles to prevent the coil from moving; the use of a tie-down restricting the coil from moving forward; and the use of a tie-down restricting the coil from moving backward. The regulation also prohibits crossing tie-downs in an “X-pattern” through the coil’s eye. For every 10,000 pounds of coil, at least one chain must secure the coil to the truck’s bed.

“K & L’s method also provides more safety to its employees by simplifying the securement process,” the company wrote. “A single strap is easier to thread through the coil’s eye than four heavy steel chains, each weighing 30 pounds. Since each employee transports roughly 20 steel coils per day, K & L’s securement methods reduces the number of times an employee must thread and unthread the steel coils from 160 to 40.”

“Because the trucks allow for transportation of more coils overall, it allows for more downtime to each individual vehicle. This affords more time for preventative maintenance to the vehicles’ engines, beds, and each of the trailer’s 32 tires. In conclusion, the carriers provide a level of safety that simply cannot be matched under the traditional chock and chain securement method.”

One comment

The company’s exemption request published in the Federal Register on May 14. The notice received one comment from an individual who said the proposed cargo securement technique may be practical if the strength of the load securement is consistently monitored by the motor carrier. The comment also mentioned that the cargo securement straps are not immune to damage and may be subject to deterioration from ultraviolet light.

“FMCSA acknowledges the concerns of commenter Bruce Grimm that the synthetic cargo securement strap and metal coil carrier proposed to be used by K & L must be inspected frequently to identify any damage that might affect the working load limit of the metal coil carrier or the single large synthetic cargo strap.”

The agency said it believes the current regulations that require all parts used to secure cargo to be in proper working order with no damaged or weakened components “ensures that the carrier will be effective in monitoring the condition of the cargo securement system.”

“FMCSA believes that the alternative cargo securement technique of metal coil carrier and the single large synthetic cargo strap is likely to provide a level of safety that is equivalent to, or greater than, the level of safety achieved without the exemption.”

The exemption is set to last until Dec. 4, 2025. LL